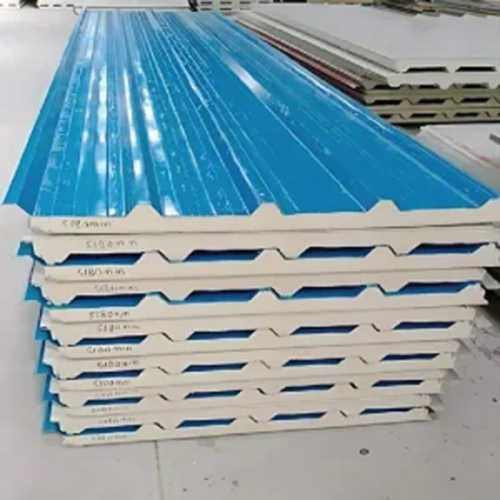

Insulated Sandwich Panels

Product Details:

- Surface Color coated

- Color Blue

- Size Various available

- Usage & Applications Industrial

- Material PPGL

- Click to View more

X

Insulated Sandwich Panels Price And Quantity

- 100 Square Foot

Insulated Sandwich Panels Product Specifications

- Various available

- PPGL

- Color coated

- Blue

- Industrial

Insulated Sandwich Panels Trade Information

- Cash in Advance (CID)

- 10000 Square Foot Per Month

- 7-10 Days

- All India

Product Description

Composite building elements intended for durability and thermal insulation make up Insulated Sandwich Panels. They offer excellent thermal resistance and structural strength because they are composed of two exterior metal sheets, usually steel, and an insulating core, usually polyurethane or polystyrene. They use cutting-edge production processes like continuous lamination and foaming and are utilised in cold storage facilities, walls, and roofing. Cutting machines, rollers, and welding equipment are examples of essential tools. These panels are used in sectors like agriculture, refrigeration, and construction. Weather resistance, ease of installation, and energy efficiency are among the advantages. These panels typically have thicknesses between 40 and 150 mm, and their size can be altered for certain uses.

FAQs of Insulated Sandwich Panels:

Q: What is the material used in Blue Insulated Sandwich Panels?

A: The material used in these panels is PPGL.Q: What is the surface finish of Blue Insulated Sandwich Panels?

A: These panels have a color-coated surface finish.Q: What is the size range available for Blue Insulated Sandwich Panels?

A: These panels are available in various sizes.Q: What is the recommended usage of Blue Insulated Sandwich Panels?

A: These panels are recommended for industrial usage and applications.Q: Are Blue Insulated Sandwich Panels available only in blue color?

A: Yes, these panels are available only in blue color.Enter Buying Requirement Details